Heat dissipation products

Graphene Flower SP

Graphene Flower SP

◎Features

Graphene Flower SP is a high-performance heat dissipation parts that uses graphene as a raw material and is molded using a special graphitization method.

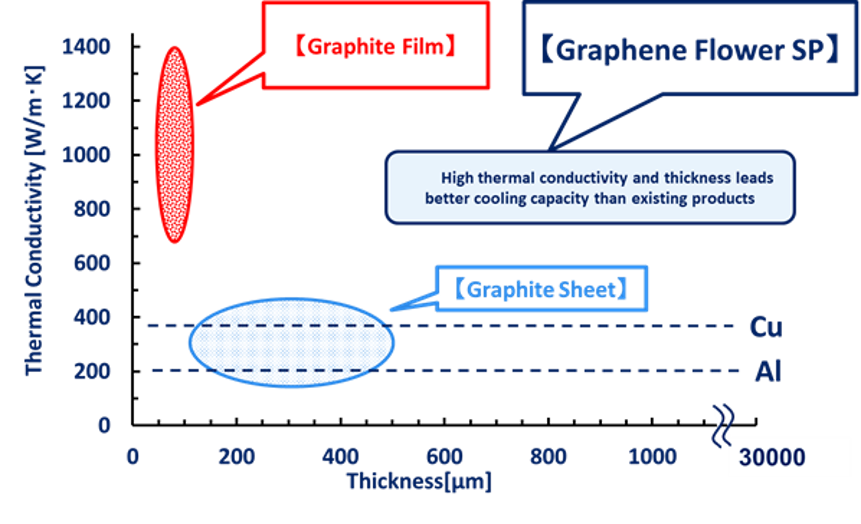

The amount of heat that can be transferred as a heat dissipation parts depends not only on the thermal conductivity but also on the thickness.Thicker ones can carry more heat. Conventional graphite heat dissipation parts have been used for limited applications due to low thermal conductivity and thick parts, in general, have low thermal conductivity.

Graphene Flower SP is made from graphene as a raw material and is graphitized by a normal temperature process at a high density, so it is possible to make parts that are 100 times thicker than before. For this reason, we successfully obtained heat dissipation parts that are thicker and with high-dissipating performance.

Fig. SP1 compares the thermal conductivity and thickness of conventional graphite materials with copper, aluminum and our graphene heat dissipation parts. Graphene Flower SP has 3 times higher thermal conductivity than aluminum, 2 times than copper, and can be 100 times thicker than conventional graphite.

Fig. SP1 Comparison of thermal conductivity and thickness of various heat dissipation parts

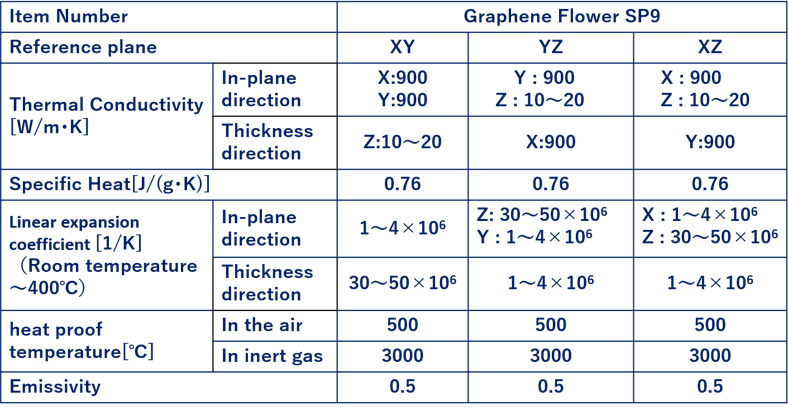

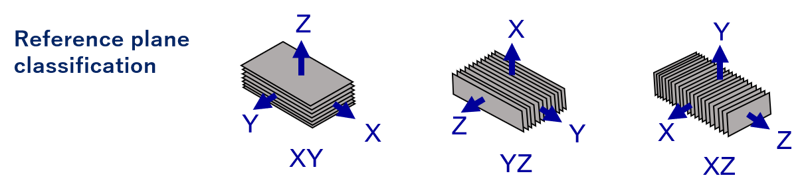

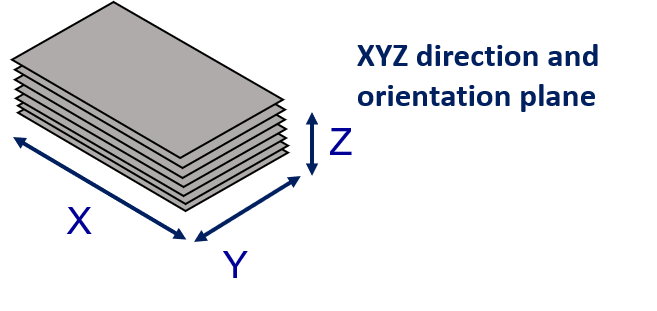

Figure SP2 shows the characteristics of SP9, our main product. Since the orientation direction of graphene of our graphene heat dissipation parts can be set arbitrarily, it is possible to manufacture YZ, XZ, etc.

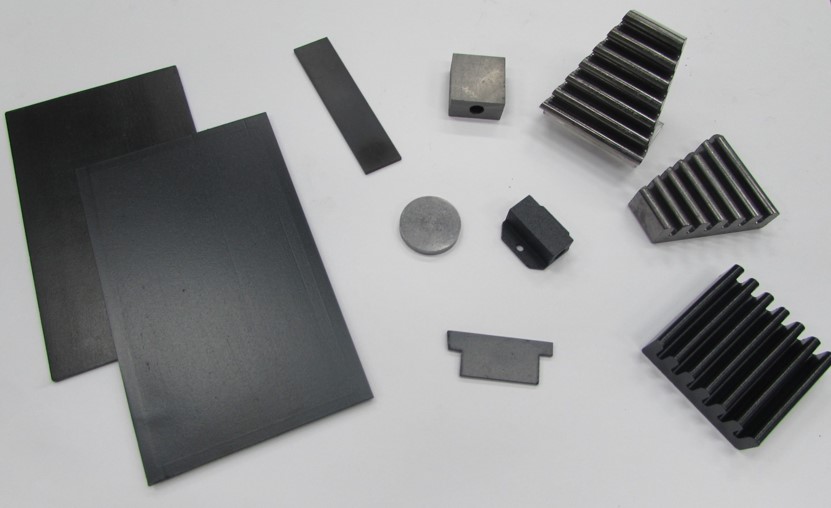

◎Application

Passive heat spreader for smartphone, tablet PC, notebook PC, etc.

High thermal conductive hybrid parts as substitute of aluminum and copper for PC, data center, LED, electronic devices in vehicles and others.

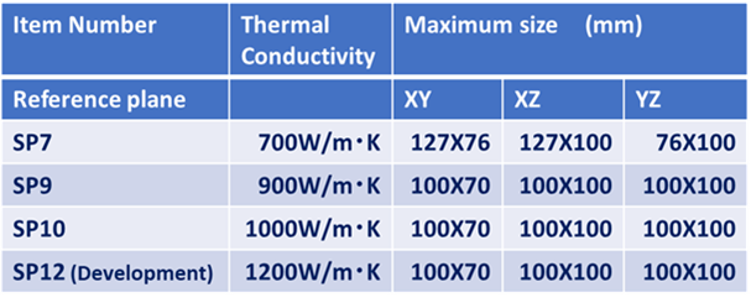

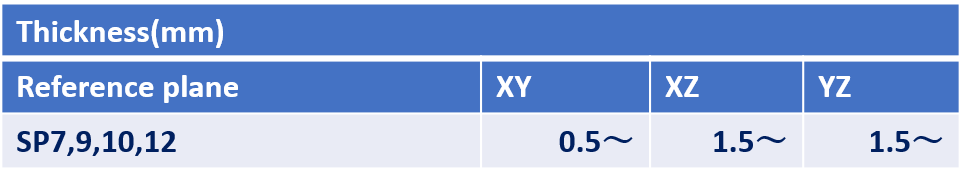

◎Product Composition/Specification

Heat dissipation products(details)

Heat dissipation products(details)

Heat Dissipation produsts(details)